Tuag-cam khwb cia kev cai heatsink rau Radiator

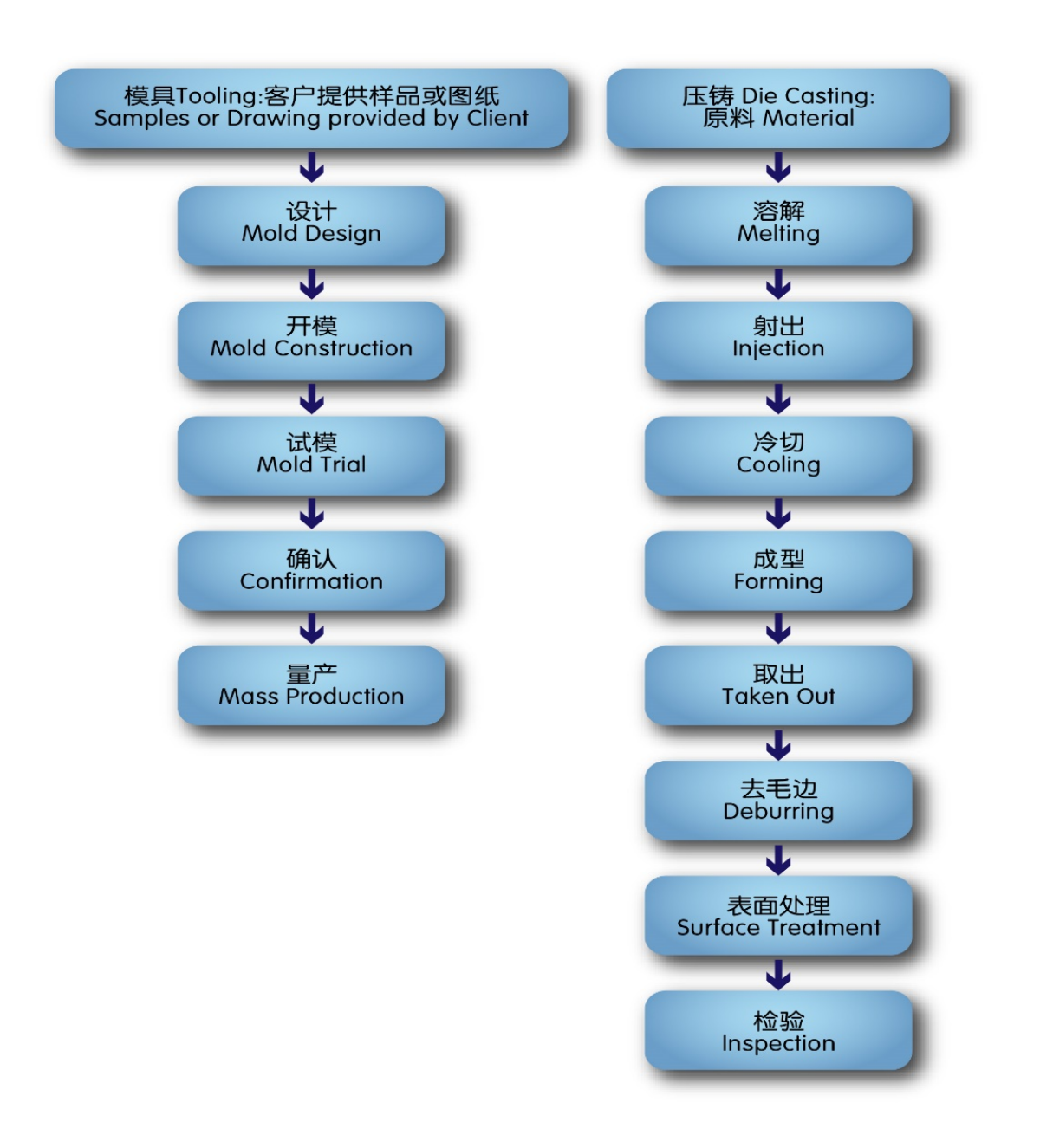

Cov txheej txheem ntawm lub dab dej kub

Tooling tsim

Kev kub siab tuag casting

Txiav

Deburring

Xuab zeb blasting

Nto polishing

Hmoov Txheej

CNC tapping & machining

Helical ntxig

Kev kho saum npoo

1. Tshuaj oxidation

2. Kev kos duab

3. Electrophoresis

4. Anodizing

5. hmoov txheej

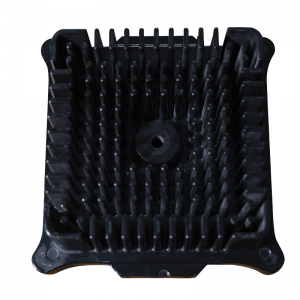

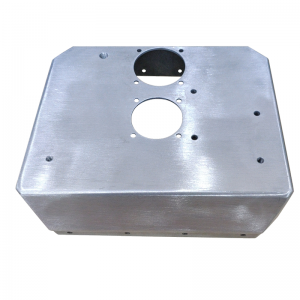

Tuag cast heat sinks

Tuag cam khwb cia cua sov dab dej yog zoo meej yog tias koj xav tau ib qho kev cai tsim aluminium kub dab dej.Lawv yog tsim los ntawm forcing ua kua txhuas nyob rau hauv siab siab mus rau hauv steel pwm .Tuag casting kub dab dej yog nrov nyob rau hauv lub lag luam vim hais tias nws yog ua los ntawm txhuas alloy.Qhov no yog cov khoom siv rau kev tuag casting kub dab dej.Cov txheej txheem tuag casting no tsim nyog ua tau raws li txhua qhov kev xav tau thiab ua tiav sai.

Lub sij hawm txhuas ceev tsuas yog 35-40 hnub

High Performance ntawm anodized nto tiav

Siab nruj qhov ntev tswj tsis pub dhau +/- 0.05mm

Engineers pab ua tiav los ntawm kev tsim mus rau kev tsim khoom

Cov txiaj ntsig ntawm Die Cast Heat Sinks

Piv nrog rau lwm txoj kev tsim khoom, tuag casting muaj cov txiaj ntsig hauv qab no:

1.Produce complex 3D duab uas tsis tau nyob rau hauv extrusion los yog forging

aluminium kub dab dej, thav duab, vaj tse, enclosure thiab fastening ntsiab tuaj yeem ua ke hauv ib qho casting

2.Qhov tuaj yeem raug cored hauv tuag casting

3.Tus nqi ntau lawm thiab tus nqi qis

4.Tight tolerances

5.Dimensionally ruaj khov

6. Secondary machining tsis tas yuav tsum tau

Muab cov chaw tiaj tus tshwj xeeb (zoo rau kev sib cuag ntawm lub dab dej kub thiab qhov chaw)

Corrosion kuj tus nqi ntawm zoo mus rau siab

Kingrun txheej txheem ntws

Piv nrog rau lwm txoj kev tsim khoom, tuag casting muaj cov txiaj ntsig hauv qab no:

1.Produce complex 3D duab uas tsis tau nyob rau hauv extrusion los yog forging

Thaum tshav kub kub dab dej, thav duab, vaj tse, enclosure thiab fastening ntsiab tuaj yeem ua ke hauv ib qho casting

2.Qhov tuaj yeem raug cored hauv tuag casting

3.Tus nqi ntau lawm thiab tus nqi qis

4.Tight tolerances

5.Dimensionally ruaj khov

6. Secondary machining tsis tas yuav tsum tau

Muab cov chaw tiaj tus tshwj xeeb (zoo rau kev sib cuag ntawm lub dab dej kub thiab qhov chaw)

Corrosion kuj tus nqi ntawm zoo mus rau siab

Zoo heev EMI kev tiv thaiv RFI