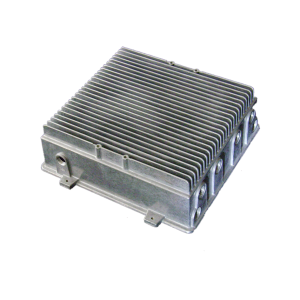

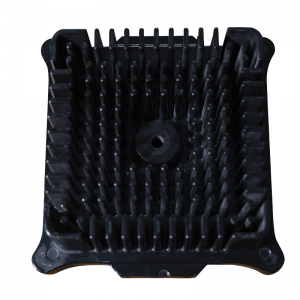

Diecast txhuas heatsink npog thiab lub cev ntawm cov khoom siv telecom

Tuag Casting Feature:

Kev siv tshuab die casting yog ib txoj kev tsim khoom zoo heev uas tuaj yeem tsim cov khoom uas muaj cov duab nyuaj. Nrog kev siv tshuab die casting, cov fins heatsink tuaj yeem koom ua ke rau hauv lub thav duab, lub tsev lossis lub qhov rooj, yog li cua sov tuaj yeem hloov pauv ncaj qha los ntawm qhov chaw mus rau ib puag ncig yam tsis muaj kev tiv thaiv ntxiv. Thaum siv rau nws lub peev xwm tag nrho, kev siv tshuab die casting tsis yog tsuas yog ua tau zoo heev rau kev ua haujlwm thermal, tab sis kuj tseem txuag tau nyiaj ntau.

Qhov Zoo ntawm Die Casting Aluminium Heatsink

Qhov zoo lossis qhov tsis zoo ntawm lub tshuab cua sov die-cast nyob ntawm hom khoom siv uas nws tau tsim. Piv txwv li, txhuas yog cov khoom siv feem ntau siv los tsim cov tshuab cua sov die-cast. Qee qhov zoo tseem ceeb ntawm cov tshuab cua sov die-cast tau teev hauv qab no:

1. Ua ntej tshaj plaws, koj yuav tsum pom tias cov cua sov uas tuag-cast ua haujlwm tau zoo dua rau cov khoom siv hluav taws xob.

2. Cov cua sov uas raug pov tseg muaj feem cuam tshuam rau cov txheej txheem casting, yog li ntawd, lawv tuaj yeem muaj nyob rau hauv ntau hom loj.

3. Cov nplaim ntawm cov cua sov uas raug hlawv yuav muaj nyob rau ntau qhov chaw, duab, thiab qhov ntau thiab tsawg.

4. Muaj kev txo qis qhov nyuaj hauv cov qauv tsim heatsink die-cast. Yog li ntawd, muaj kev txo qis qhov xav tau los ua machining.

5. Koj tuaj yeem ntxiv cov channel sib txawv kom dissipate cua sov los ntawm lub tshuab cua sov tuag-cast.

6. Cov cua sov uas raug hlawv yog pheej yig dua thiab tuaj yeem muag tau ntau heev.

7. Koj tuaj yeem muaj ntau yam khoom orientation hauv die-cast heatsinks. Txawm hais tias cov khoom orientation yog dab tsi los xij, cov cua sov ntws tau tswj hwm kom zoo.

8. Cov chaw tsim khoom kuj tseem tuaj yeem hloov kho cov cua sov uas raug hlawv raws li koj xav tau.

9. Peb tuaj yeem tsim ntau hom heatsink npog, tsev nyob, lub hauv paus rau kev sib txuas lus, khoom siv hluav taws xob.

Cov Ntsiab Lus

Cov Kev Xyaum Zoo Tshaj Plaws rau Kev Tsim Khoom Siv Aluminium Casting: Tsim rau Kev Tsim Khoom (DFM)

9 Yam Yuav Tsum Xav Txog Thaum Yuav Tsim Aluminium Die Casting:

1. Kab sib cais 2. Cov koob ejector 3. Ntsws 4. Cua ntsawj 5. Phab ntsa tuab

6. Cov Fillets thiab Radii7. Cov Thawj Coj 8. Cov tav tav 9. Cov hauv qab 10. Cov Qhov thiab Cov Qhov Rai